Why Fortified Rice?

Rice is a staple food for more than half of the global population, providing more than 20% of the world’s calorie intake. Rice is widely consumed in many developing countries, where ‘hidden hunger’ is an issue. This offers a unique opportunity for nutrition improvement in the form of rice fortification.

There are multiple factors to consider when developing sustainable and effective rice fortification programs, which have a positive impact on public health, including which vitamins and nutrients to include and at which level, the how to integrate fortification into the rice supply chain, and ensuring it meets all regulatory requirements.

A Global Need for Nutrients

As one of the world’s most widely consumed foods, rice plays a significant role in many diets around the globe. In low income countries, it can make up to 70% of an individual’s calorie intake. Though it is a great source of energy, it is a poor source of micronutrients and has a low overall nutritional value beyond carbohydrates and protein. This is because the milling process that produces white rice removes the fat, as well as the more nutrient-rich bran layers. Parboiled rice, brown rice and bio-fortified rice (for example high-zinc rice) are more nutritious compared to white rice in one or a few essential micronutrients. This is due to different paddy processing or utilizing more nutritious rice varieties. In this article the focus will be on post-harvest rice fortification – the addition of several essential vitamins, minerals and potentially other nutrients to make any rice variety more nutritious post-harvest and after paddy processing.

Vitamin and mineral deficiencies are also an issue outside of low-income countries, affecting most regions worldwide at varying levels. While malnutrition is often associated with those not consuming enough calories, the lack of essential vitamins and minerals in ample or high calorie diets is a prominent issue, known as ‘hidden hunger’.

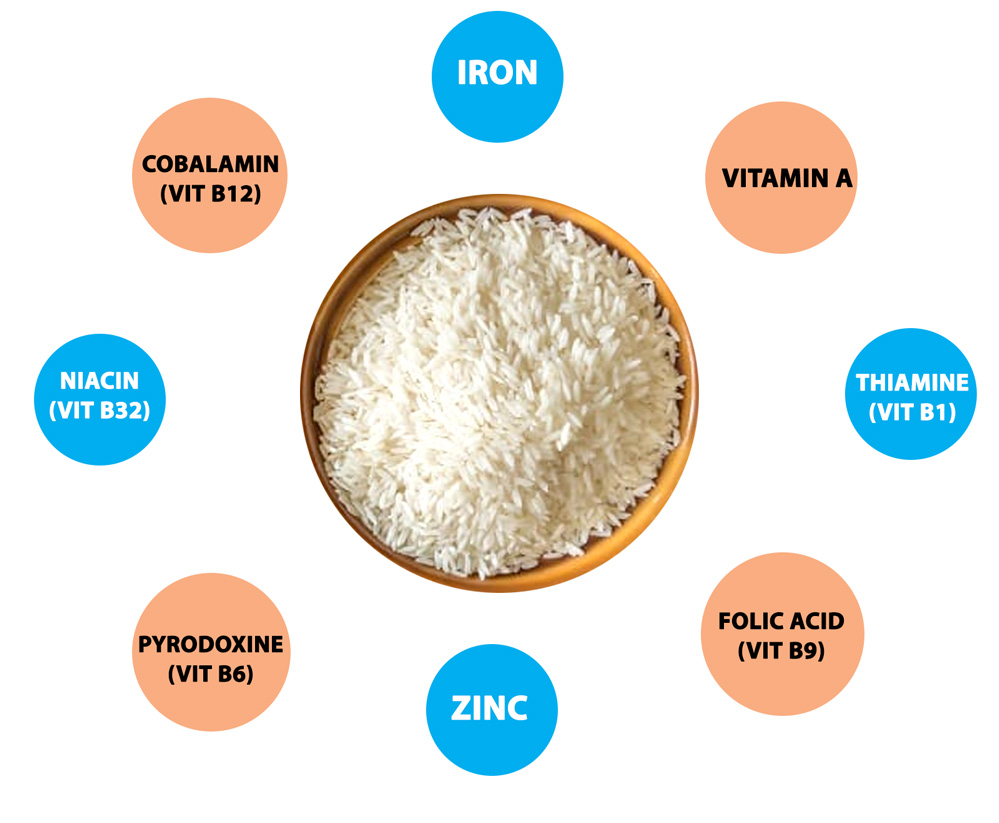

The popularity of rice presents an opportunity to fill the nutrient gap in rice-eating populations worldwide by increasing the nutritional value of rice. A wide variety of vitamins, minerals and other nutrients such as amino acids and fibers can be added post-harvest to effectively address malnutrition and contribute to Sustainable Development Goal 2.

A growing number of countries have mandated rice fortification and are fortifying rice distributed through social safety nets (for example school feeding), or have set voluntary rice fortification standards to address hidden hunger.

Methods to Make Rice More Nutritious :

Rice can be made more nutritious by adding vitamins, minerals and other nutrients to replenish micronutrients lost in the milling process and reinforce its nutritional value. Fortified rice can be adjusted based on the nutritional needs and can made to resemble the different rice varieties.

There are different methods to make rice more nutritious post-harvest:

Dusting –

This is where rice kernels are dusted with a micronutrient powder, relying on an electrostatic force to bind the dry powder to the surface of the grain. Fortified rice produced by dusting cannot be washed or cooked in excess of water.

Coating –

a method that involves the use of a fortificant mix and ingredients such as wax or gum to ‘fix’ the micronutrient layer being sprayed onto rice. The produced fortified kernels are blended with regular rice, typically at 0.5 – 2% ratio.

Hot or Warm Extrusion

hot extrusion is considered the most robust method of rice fortification, supported by extensive evidence base to have a positive impact on micronutrient deficiencies. Broken rice grains are ground into rice flour, then mixed with water and the required nutrients to produce a dough. The fortified dough is then passed through an extruder to produce the fortified kernels, which are then blended with regular rice typically at 0.5-2% ratio. The temperature at which the extrusion takes place determines if we speak of hot or warm extrusion and has an influence on the rice starch gelatinization and thus firmness of the produced fortified kernels.

Selecting an appropriate technology and fortificant forms to fortify rice post-harvest is crucial to successfully improve micronutrient health. In countries where rice is frequently washed, soaked or cooked in excess water, dusting will not be effective, and a coating technology needs to be rinse resistant to be effective. To have a positive health impact, fortified rice needs to have good:

- Stability during transport and storage

- Retention during cooking & preparation

- Consumer acceptability

- Absorption by the body of the used micronutrients

Hot extrusion is supported by a robust evidence base and shows excellent consumer acceptability. The fortified rice looks, cooks and tastes the same as non-fortified rice.

Benefits of Fortification and Beyond :

Safe Agritrade offers a wider portfolio of high quality and safe nutrients fortified Rice and Custom nutrient premix fortified Rice. We are also a registered member to import Rice to Papua New Guinea. We offer mostly hot extrusion Fortified Rice kernels to ensure high-quality micronutrients remain stable without requiring a behaviour change or further education for the end consumer.

We offer varieties of packing as per customer’s requirement starting from 500gms to to 40kgs.

WHY SAFE AGRITRADE ?

Safe Agritrade offers a wider portfolio of high quality and safe nutrients fortified Rice and Custom nutrient premix fortified Rice. We are also a registered member to import Rice to Papua New Guinea. We offer mostly hot extrusion Fortified Rice kernels to ensure high-quality micronutrients remain stable without requiring a behaviour change or further education for the end consumer.

We offer varieties of packing as per customer’s requirement starting from 500gms to to 40kgs.

The overarching purpose of fortified rice is to meet nutritional goals for the end consumer, but in order for nutritional programs to reach their full benefit, fortification programs need to meet certain requirements in order to be effective.

Ease of use – This is one of the biggest benefits. As a widely used staple food, it is simple to replace standard rice with fortified rice to boost the nutritional profile of a simple diet. With certain methods of fortification, consumer usage is key in effectiveness. However, advances in fortification technologies, such as the use of hot extrusion, also ensure the added high-quality micronutrients remain stable without requiring a behaviour change or further education for the end consumer.

Cost – The specific costs of fortified rice depend on several factors, such as the scale of the operation and the blending ratio of fortified to non-fortified kernels – most commonly 1% -2%. However, rice fortification costs are small compared to the wide-reaching benefits. The cost impact is around 1.5% -3%, yet such strategies can help tackle malnutrition at both a population and personal level.

Consistency for consumers – It looks, cooks, and tastes the same as non-fortified rice. This is great for individuals in low income countries, where awareness and education on both nutrition and usage of fortified rice may be lacking.

Reducing ANAEMIA

Its one of the best way or practice to have Fortified rice to reduce Anaemia.

Anaemia is a condition in which a person has low levels of red blood cells or concentration haemoglobin, which reduces the capacity of their blood to carry oxygen. The most common causes of anaemia are nutritional deficiencies, particularly iron deficiency. Indian government is planning to fortify rice with iron, folic acid and vitamin B-12.

Market differentiation for brands –

Fortified rice can also be customized for specific needs. It presents a solution for health-conscious consumers looking for new ways to reach specific health benefits.

Reducing micronutrient deficiencies for governments and schools –

There’s also the opportunity to build fortified rice into school feeding programs to have better health for our next generation.

Rice fortification is currently compulsory in six countries: Costa Rica, Nicaragua, Panama, Papua New Guinea, Solomon Islands and the Philippines. It is also mandatory in six states in the US.